Beer Studio is a local microbrewery in Umeå here in the North of Sweden. It is run by the well known beer journalist Darren Packman, founder of the Beer Sweden website. Darren regularly hosts beer tastings, which I’ve been to three of. At the end of the third tasting (which was a beer and cheese tasting – super delicious) I approached Darren and asked him if I could spend a few hours at his brewery learning about how things worked. He said that absolutely I could and we agreed to speak by email. A few weeks later I got my chance and went.

This will probably be a picture light post due to my only taking a few. I did tweet about it a bit, so you can read back to that if you like (Date was October 14th), but you’ll not learn anything new that you didn’t get from this blog post. I’d also like to note that I’ll be talking highly of Beer Studio and their products in this post. I’m in no way paid to do this, and gain nothing for doing so. This is purely my opinion.

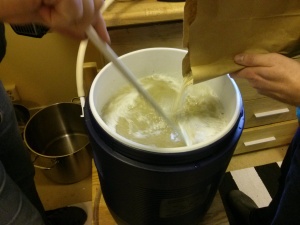

When I arrived at Beer Studio they were shifting one of their new beers from the primary fermenter to secondary and preparing to brew a new batch of their Long Play Pale Ale. After that was done I hosed down the primary tank to try and clean it up as much as possible as Leif (the brewer) cleaned the mash tun. After that was all done we started filling the mash tun which basically involved a hose pouring hot water into it.

Next we measured all the grains and crushed them with a large automatic mill. Then we took the buckets of grain and dumped them into the mash. Each bucket (there was 2 or 3) weighed in around 110kg.

At some point during the process we turned off the water and then the mash spent several hours working. The tun had a giant steel two pronged fork that turned keeping the grains moving and ensuring that the heat was evenly spread out.

While we waited for the mash to do its work we cleaned the bottling system because they had a batch of Spin Back in the carbonation tank that was ready to be bottled. Then we tried to bottle 8 bottles in advance without the machine (they needed a few done in advance) but just trying to use a hose resulted in them foaming badly and we ended up with 4 partial bottles of beer.

I ended up being able to take three of those bottles with me (Darren poured the fourth for tasting purposes) at the end of the day, and that beer was absolutely fantastic. If you’re ever at a bar that serves it, I highly recommend.

After a quick break for lunch (I ate a huge meal before arriving and was starving within 3 hours, working in a brewery is hard work) we cleaned the boil… pot? When you’re putting almost 2000L into it I don’t think it is called a pot anymore. We then started the sparging process and transferring the wort.

The sparge arme is home-made, four copper tubes with holes punched in that are all connected at a central point and attached to a long piece of metal that holds it in place above the mash tun. They said they originally made the arms too long and kept having to adjust the amount of water flowing in, but after shortening it to the current length it fills the tun at the perfect rate.

Once this process was started we hooked up the bottling machine and they showed me the bottling process, which was very fast and efficient. By this time evening had set in so I thanked them for having me in and called it a day.

Working in a brewery

Working in a brewery, as I mentioned earlier, is a lot of hard work. There is plenty of heavy lifting and moving things around, and a lot of waiting and cleaning in between. It isn’t a glamorous job but it is a lot of fun. I asked Leif what his favourite part of being a brewer was and he said crafting new recipes and tasting the results afterwards. Brewing isn’t all there is to a brewery by any means though. Darren spent a lot of time during the day working on logistics, selling beer and marketing their beer. I spent most of my day with Leif with Darren showing up sporadically to talk to us about stuff.

Homebrewing vs Industrial Brewing

A couple of differences I learned about brewing on a large scale vs homebrewing are:

1) Scaling recipes – This is doable certainly, but not a matter of just scaling up amounts. In the grain bill you have to account for differences in efficiency between your homebrew setup and the brewery setup. Hops also have a different ratio, if you scaled up the number of hops directly from your homebrew your pleasantly bitter IPA would be come undrinkable due to excess bitterness.

2) The volume. A brewery is LOUD. Not like you’re in a night club loud but more like there’s a million things making noise at once loud. You have pumps running, motors turning, liquids moving through pipes, etc. It was never a problem for conversing (unless we were in the mill room) but stepping outside when I left was definitely notable in the volume difference. Homebrewing by comparison has very little noise. The boil pot a bit while it is boiling but that is it.

And Finally

All in all the whole day was a lot of fun and I am thankful for Leif and Darren for letting me join them. There’s a lot I haven’t mentioned in this post in part because it has already been a month and a half since I was there so I don’t recall all the details, and in part because the post would likely never end if I wrote everything. Beer Studio makes fantastic beer and is run by some really nice guys. If you ever have the chance, pick up one of their beers and support them.

Recent Comments